Simulation of an industrial burner

Pieter van Heerbeek

Site of the project:

DLF Sustainable

Postbus 1077

2600 BB Delft

start of the project:

February 2007

In December 2007 the

Interim Thesis

has been appeared and a

presentation has been given.

The Master project has been finished

in July 2008 by the completion of the

Masters Thesis

and a final

poster presentation has been given.

There are videos available from an

industrial burner

and the

Rijke tube.

For working address etc. we refer to our

alumnipage.

Summary of the master project:

DLF Sustainable is a specialist in the field of thermodynamical

applications. Examples are: sludge dryers/incinerators, heaters, food

dryers, gasification units, etc.

One of our top products is the Pulsed Combustion Burner suitable for

small and large power capacities. With this type of burner we achieve

production increase as high as 40 % due to the extreme increase of

heat exchange capacity. Depending on the application we achieve often

a 10 tot 50 % saving on energy.

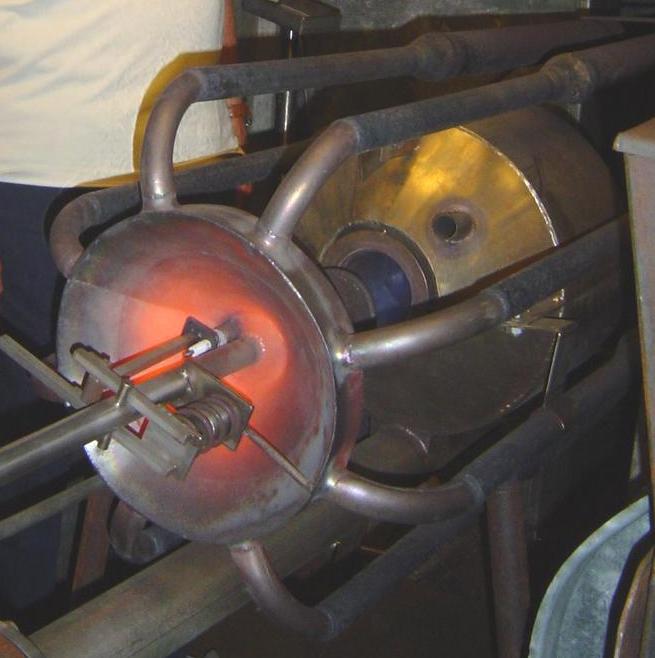

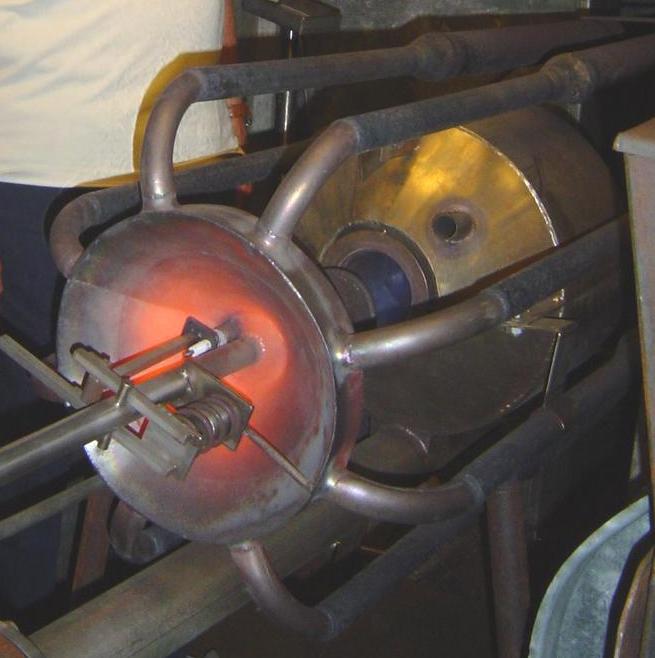

Advanced 5 MW pulsed combustion burner

In this master thesis project, research is planned to have a better

understanding of the pulsed combustion burner. As a first start we

investigate the modelling and simulation of a Rijke

tube. Research questions are:

enhancement of the efficiency, optimization of the geometry,

understanding the frequency of the oscillations etc.

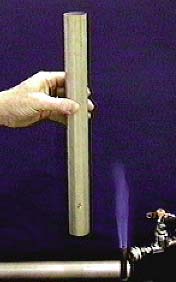

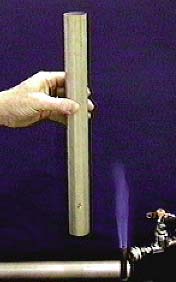

Rijke tube and simple model

Measurements

Contact information:

Kees

Vuik

Back to the

home page

or the

Master students page of Kees Vuik

![]()

![]()