Modeling of New Processes and Refractory Materials in Industrial Applications

Project Description of Open PhD Position

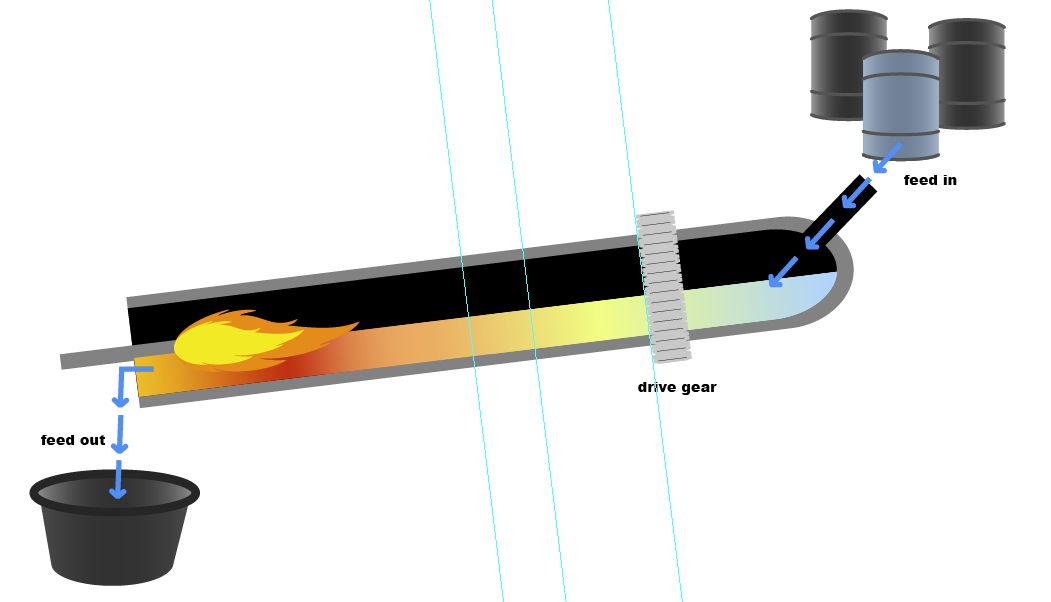

In this project we intend to develop combustion

models for industrial furnaces that will

enable the accurate prediction of the internal temperature and radiative heat transport

distribution as well the motions of the granular material being processed through the ovens. These models

are a extension of those developed in a run-up to this project and will generate the information that

is urgently needed in the optimization of the operation of existing installations and of the

design of future ones at our industrial partner.

Modeling of Internal Turbulent Combustion

We intend to develop three-dimensional premixed and non-premixed internal combustion models to predict the

temperature and radiative heat transfer distribution in the furnaces. These profiles have

an immediate impact on the quality of the final product being produced in the furnace. Our models will aid

in increasing the throughput and fuel efficiency of the furnaces and will allow to predict the amount of

toxic NOx formation. This in turn will enable to study the

effectiveness of different catalytic systems and

other systems put in place to reduce the amount of toxic gasses produced. Our combustion models will also

serve to access the effect of changes in different factors that allow to influence temperature

and radiative heat. These factors include: the operating conditions, the flux of in and outgoing air,

the burners and burner configurations, the insulating linings and the foreseen change in fuel composition

due to the new gas supply in the Rotterdam Harbour area.

The field of numerical combination is a very active area of research. The industrial context of our research

project necessarily requires making a number of simplifying assumptions. Turbulence phenomena however do not

allow to consider simply two-dimensional configurations. This raises the difficulties of the mesh generation

in three dimensions taking the complex burner or burner configurations into account. The modeling the

combustion can be done using either simplified eddy break-up models or more involved probability density

formulations. Different number of species and stages in the chemical reactions can be taken into account.

In this project suitable choices for the combustion mechanism will have to be made.

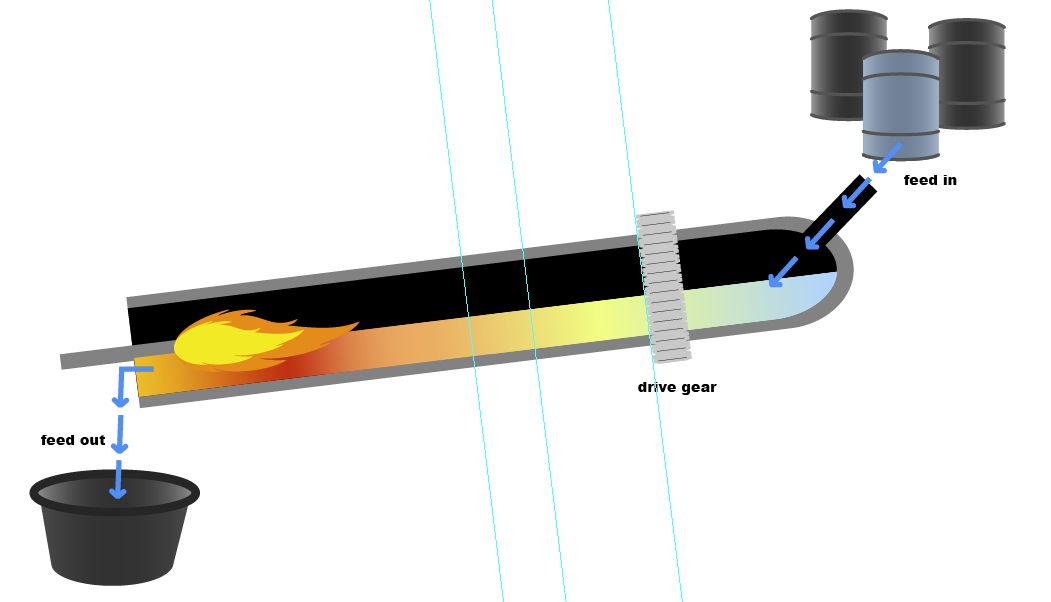

Modeling of Granular Material Flow

We intend to develop Euler-Euler and Euler-Lagrange models for the transport and mixing of

granular material

in the furnaces considered. In the former type of models, the

motion of the individual particles is tracked. The physical equations governing the motion

of the individual particles are easy to simulate. In case of a large number of particle however,

this so-called discrete element method quickly becomes computationally unattractive. In the

latter approach a granular material and the surrounded space are modeled as two fluids that

exchange momentum in their motion. Such two-fluid models are computationally attractive at

the expense of requiring application dependent calibration. In the hybrid approach that we intend

to pursue, the discrete element method will be used to calibrate the two-fluid approach. The

models will be validated on reduced and full scale installations.

Previous Work in Turbulent Non-premixed Combustion in Rotary Kilns

The modeling of the turbulent combustion in rotary kilns was carried out by Michele Pisaroni from September 2010 until July 2012.

Joint TU Delft/Almatis B.V. Seminar Held on June 9th, 2011

- Program .pdf

- Fluid and Combustion Modeling .pdf

- Heat Transfer .pdf

- Granular Motion .pdf

Woudschoten 2011 Meeting

- Single Slide Presentation .pdf

- Poster .pdf

CD-Adapco 2012 Users Meeting

- Submitted Paper .pdf

DIAM TU Delft Technical Report

DIAM TU Delft Technical Report .pdf

DCSE Seminar on Sooth Formation Held on May 15th, 2012

- DSCDE Seminar .pdf

Previous Work in Turbulent Non-premixed Combustion in Shaft Kilns

The modeling of the turbulent combustion in shaft kilns was carried out by Cheng Lu (visiting PhD student from Tsingua University) from September 2010 until July 2012.

Slides of the COMSOL Users Meeting Rotterdam 2013

- Slides .pdf

Previous Work in Granular Bed Motion

The modeling of the motion of and heat absorption by the granular bed is the subject of the master thesis that Miguel Romero defended in August 2012.

Progress Meeting at Almatis on May 22nd, 2012

- Slides .pdf

Master Thesis on Modeling of the Motion of the Granular Bed

- Master thesis of Miguel Romero .pdf

Woudschoten 2012 Meeting

- Poster .pdf

Previous Work on the Modeling of Sintering Reactions

The modeling of the sintering (pore shrinkage and grain growth) in a shaft kiln is the subject of the master thesis carried that Bonnie Fan defended in August 2013.

Master Thesis on Modeling of the Sintering Reactions

- Master thesis of Bonnie Fan .pdf

This page is maintained by Domenico Lahaye.